What is Acrylic and How Does it Work? The Coolest Acrylic Projects!

What is Acrylic and How Does it Work?

Poly(methyl methacrylate) (PMMA) is a transparent thermoplastic, most commonly called Acrylic or Plexiglas. PMMA is the scientific name for the material derived from the chemical compound. PMMA is most commonly called Acrylic by most plastic industry professionals and individuals familiar with plastic materials. Plexiglas (commonly misspelled “plexiglass”) is arguably the most popular well known trade name for acrylic and used by the average consumer. Other trade names include Optix, Lucite, Chemcast and Polycast.

Acrylic or (PMMA) is often used as a lightweight or shatter-resistant plastic alternative to glass. Acrylic is an economical alternative to polycarbonate (PC) when extreme strength is not necessary. Acrylic is a clear thermoplastic with about 92% transparency, making it useful in many optical applications. It is also a good electrical insulator and resistant to weathering. It is often preferred because of its moderate properties, easy handling, durability and low cost. Chemically, it is the synthetic polymer of methyl methacrylate.

The material was developed in 1928 in various laboratories by many chemists such as Otto Röhm, William Chalmers and Walter Bauer. Rohm and Haas Company first brought the material to market in 1933, under the trademark Plexiglas. Although it is not technically a type of glass, the substance has sometimes historically been called acrylic glass.

Acrylic known for its flexibility and versatility; enables it to be used for many different projects. It’s surface is as hard as copper or brass. It is also versatile, in that it can be painted, glued, screen printed, routed, drilled, or sawed. You’ve probably encountered acrylic in your everyday life. Skylights, aquariums, dentures, and bone cement are all made of plexiglas (acrylic). We’ve appreciated the versatility and variety of uses of acrylic for quite some time here at Akriform. Our Custom plastic products play to all the benefits of acrylic, while creating a product specific to our customer’s needs.

Plexiglas, Breaking Onto the DIY Scene

Since it was trademarked in 1933, Plexiglas (acrylic) has become an increasingly popular material for a variety of projects. Although we will highlight some of the more amazing commercial projects below, it is none the less also popular for many DIY (Do-It-Yourself) projects including:

– home and office decor and furniture

– replace traditional white board

– jewelry

– garden greenhouse

– photo frames

– window panes

– LED sign

Several Cool Commercial Acrylic Projects:

“Ghost” Car from GMC Made of Plexiglas

“Ghost” Car from GMC Made of Plexiglas

Perhaps the coolest plexiglas project is also the earliest. In 1939, Rohm & Hass built the Pontiac ‘Ghost Car,’ America’s first transparent car. Rohm and Haas Company trademarked Plexiglas in 1933. The unique design allows people to see the ‘guts’ of the car through the plastic. It’s still a popular project–and very valuable–as it was auctioned off for $308,000 in 2011. It cost $25,000 to make the car in 1939.

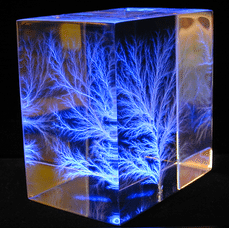

Captured Lightning Acrylic Cube

Captured Lightning Acrylic Cube

Another cool project is “captured lightning” sculptures. These sculptures are made by injecting electrons into a specimen of acrylic, which is a wonderful insulator, clearer than glass, and durable. Sculptors use a 150 kW particle accelerator to inject the electrons. Once the electrons are injected, the acrylic traps them inside, and the sculptors poke at the acrylic with metal prongs, which force the specimen to discharge. This causes a ‘breakdown’ that is very much like miniature lightning. This blast, which occurs in less than 120 billionths of a second, creates a ‘lightning fossil’ that lasts permanently inside the acrylic. This has the appearance of a tree-like pattern.

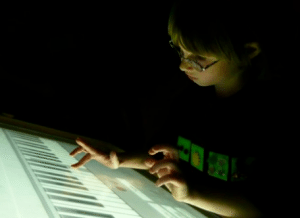

Giant Acrylic Touch Screen

Giant Acrylic Touch Screen

Another current project is the giant touch screen, which has the potential of being the size of a table. There are possibilities of restaurants using table sized touch screens on their table tops for customers to view the menu and place their orders. Of course, the screen itself would be made out of acrylic because of its durability and high insulation quality.

As you can see, rather you call it PMMA, acrylic, or plexiglas the possibilities are virtually endless. If you can dream it, Akriform can create it. We’ll work with you through every step, ensuring we are on the same page before moving into production. In addition, we pride ourselves as being innovators and focus on research and development to remain at the top of the field always. Make your vision a reality with Akriform!

Contact us or place an order today!

Image Credits:

Newsroom desk by Akriform

Art Installation with fire by Akriform

Ghost car – http://rumors.automobilemag.com

Lightning captured in Plexiglas – http://capturedlightning.com/frames/lichtenbergs.html

Plexiglas touch screen – http://pixelverse.org/portfolio/multitouchtable/